Early in 2014 the NEWEA Safety Committee emailed its annual Wastewater Facility Safety Survey for the 2013 work year to facilities throughout the six New England states. The purpose of the annual survey is to:

- Collect regional incident and injury statistics and publish them for use by all wastewater professionals to benchmark their safety programs.

- Identify those areas and activities where injuries are occurring so that facility managers can better focus their safety efforts.

- Gather information regarding the status of safety programs at wastewater treatment facilities throughout New England.

For the 2012 work year, 40% of those facilities returning surveys reported at least one incident. For 2013, that rate decreased to 28%. There were a total of 56 injuries reported, with 25 of those causing lost workdays – meaning almost half of incidents reported were severe enough that the employee incurred lost workdays. Those 25 injuries resulted in 411 total lost workdays.

For the 2012 work year, 40% of those facilities returning surveys reported at least one incident. For 2013, that rate decreased to 28%. There were a total of 56 injuries reported, with 25 of those causing lost workdays – meaning almost half of incidents reported were severe enough that the employee incurred lost workdays. Those 25 injuries resulted in 411 total lost workdays.

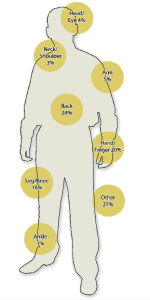

The body part most frequently injured in 2013 was the back. The majority of those injuries were strains caused by lifting, pulling, or reaching (e.g., turning a wrench on a fire hydrant, opening a chain valve, pulling the stop gate at the aeration tank, etc.).Hand injuries were the second most common and the majority of those were cuts caused by “struck against” injuries (e.g., cleaning out the screw press, pump repair, sawing pipe, etc.).

Soft tissue and muscle injuries in the back can be costly, involve surgery, require painful rehabilitation, and limit the injured person from returning to their previous level of function, affecting their life at work and at home. Additionally, once a person experiences these types of injuries they are often more susceptible to future occurrences. Completing basic stretching and warm up exercises before engaging in physical activity can help to prevent these injuries. Another effective way to prevent back injury is to implement a safety program that focuses on safe work practices to reduce the hazards of lifting (e.g., think about things like: using mechanical aids when available; assigning two people to lift the load; alternating heavy tasks with lighter ones to reduce the buildup of fatigue, etc.).

Machine guarding and safety gloves are common ways to approach hand safety hazards such as using tools, operating equipment, handling rough materials and chemicals, and stacking and storing objects. In addition to these safeguards, make sure you also take a moment to think about the task you need to perform and the potential hazards involved. What if…the knife slips while I am stripping this wire? Will I cut myself? What if…the screw driver slips off this stubborn screw I’m trying to remove from this box in my hand? Will I punch the screwdriver through the palm of my hand? What if…..there’s a little bit of chemical left in the line I’m working on? Will my hands be burned? By thinking through the potential hazards you could face, you will be better prepared to choose the appropriate means to protect yourself.

In addition to providing incident information, many of the survey respondents also expressed common concerns regarding their biggest safety challenges. The list below represents the top concerns:

- Keeping up to date with training (the availability of affordable classes; finding time to attend)

- Avoiding complacency during daily job tasks

- Workers falling, tripping or slipping

- Confined spaces

- Construction at the facility creating daily work hazards

- Funding

This information helps us to understand where the majority of our losses and challenges are coming from, and may allow us to plan resources for these areas in the future. The Safety Committee is pleased to have provided this information and we hope that members find it useful. As expected, the survey highlighted the fact that incidents are a reality in our facilities, and that additional efforts are needed to improve our safety programs and protect our personnel. The vast majority of these incidents are preventable. We would like again to thank all of the facilities that returned 2013 work year surveys and we strongly encourage all facilities to return the 2014 work year survey (watch for it in the spring of 2015) in order to help us increase the value of its results.

The following 3 facilities were each the recipients of a $100 gift card as a “thank you” for participating in the survey. Congratulations to:

New Shoreham Water Pollution Control Facility (RI)

Bellow Falls Wastewater Plant (VT)

Passamaquoddy Wastewater Facility (ME)

Respectfully Submitted,

NEWEA Safety Committee

No comments yet.